Say Goodbye to Sinking Concrete: What You Need to Know About Concrete Lifting

Settling concrete can cause a whole host of issues at your home or business. Are you worried about your grandchildren tripping on your uneven patio? Is water pooling in your driveway, breeding mosquitos? Are your garage doors refusing to close properly because of the uneven surface?

Besides these irritating issues, uneven, settled concrete makes your whole outdoor area look unkempt, no matter how much you mow, mulch, and pressure-wash.

Here at Keystone Gun-Crete, we understand how frustrating it can be to deal with settled concrete. That’s why we use innovative techniques to clean up your property’s look by lifting that concrete back into place!

Are you curious about how it works?

Keep reading to find out!

What Is Concrete Lifting?

If you want to fix your settled concrete issue without doing a complete concrete replacement, the solution is concrete lifting, which lifts the settled concrete slab back to its original position. This procedure is sometimes called “slabjacking.”

Concrete lifting works like this: trained technicians drill small holes in the concrete and inject a two-part polyurethane foam beneath the slab. This foam fills the voids that caused the slab to sink in the first place. As the foam expands, it lifts the slab and stabilizes the surrounding soil.

If you’d like a more detailed explanation, read our blog post, Concrete Lifting 101: A Guide to Restoring Your Concrete.

Later, we’ll talk more about the procedure and explore other concrete lifting methods. But for now, let’s look at what causes the problem in the first place.

The Problem of Sinking Concrete

Over time, concrete areas such as sidewalks and driveways may start to sink, settle, and crack. This is caused by a variety of factors: maybe it was installed incorrectly, maybe your land has drainage problems, or perhaps the soil wasn’t compacted properly when the concrete was first installed.

Even if concrete is installed correctly by professionals, there’s still a chance it may sink eventually, because ground is somewhat unpredictable.

If your concrete is sinking, it can cause the following issues:

1. Safety Hazards

Uneven surfaces caused by sinking concrete can create tripping hazards, especially on sidewalks, driveways, or patios, which presents a safety hazard, particularly for children and the elderly. If your sinking concrete creates uneven driveways or parking areas, it also can cause wear and tear on vehicles and other equipment.

2. Structural Damage

Minor issues can become bigger issues over time, especially if the sinking concrete is near a home’s foundation. This can lead to cracks in walls or other structural damage.

Settled concrete can also disrupt drainage, causing water to pool or drain into your basement, which is a massive headache.

3. Aesthetic Concerns

Finally, let’s be frank: settled concrete makes your home or business look unkept, uncared for, and unsightly.

Benefits of Concrete Lifting

So, what can you do about your sinking concrete?

There are various solutions you could employ, such as pouring a self-leveling compound on top or completely replacing the slab. However, the most permanent and cost-effective solution is concrete lifting.

1. Concrete lifting solves the problem

The main reason concrete lifting is a great idea is simply that it solves the problem. All the issues we discussed in the last section—tripping hazards, unsightly landscaping, drainage problems—are solved by concrete lifting.

2. Concrete lifting is cost-effective

In addition to solving the problem, concrete lifting is a highly cost-effective solution. The alternative—completely removing the concrete and pouring a new slab—takes so much more time, materials, and labor that it ends up being significantly more expensive. On the other hand, pouring a self-leveling compound might be cheaper upfront, but since it doesn’t solve the underlying issue, the slab may continue to settle and cause costly damage.

That leaves concrete lifting as the most cost-effective solution to the problem.

3. Concrete lifting is quick and efficient

Unlike concrete replacement, concrete lifting methods are quick and minimally invasive. The process usually only takes a few hours to complete. The polyurethane foam injection method we use here at Keystone Gun-Krete only requires a few small holes to be drilled in the concrete, and it cures quickly. In fact, you can usually drive on it the same day!

4. Concrete lifting is robust and long-lasting

The polyurethane foam we use for our concrete lifting is highly durable and lasts decades. It also fills the voids beneath the slab and helps stabilize the concrete, which prevents further settling and deterioration.

5. Concrete lifting is environmentally friendly

Finally, since concrete lifting reuses and restores the existing concrete instead of sending it to a landfill and using all new material, it’s an eco-friendly solution.

Now that we’ve fully explored the benefits, let’s look at concrete lifting methods and compare them to each other.

Methods of Concrete Lifting

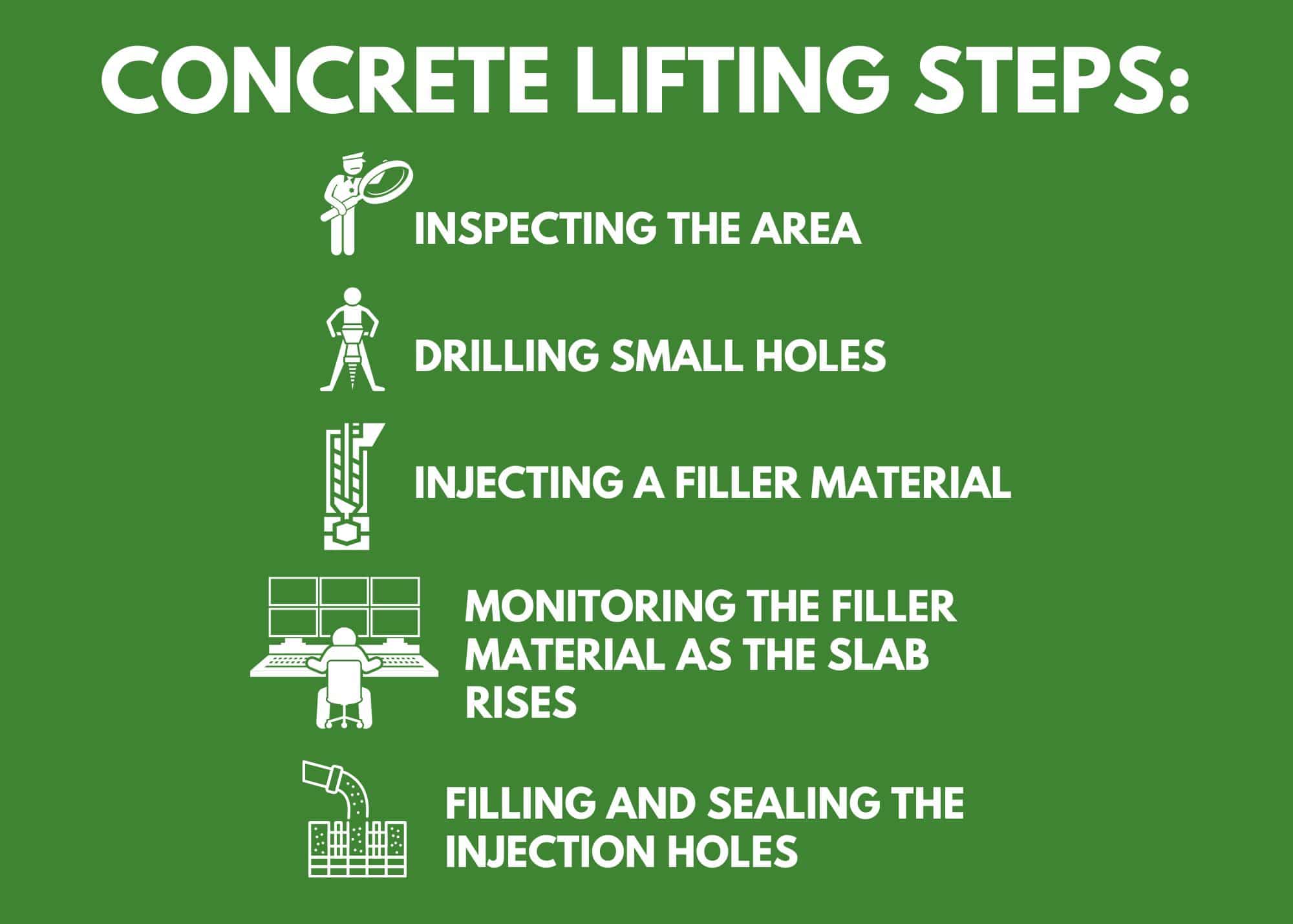

When you hire a professional concrete lifting team, they will perform the following steps:

- Inspecting the area

- Drilling small holes

- Injecting a filler material

- Monitoring the filler material as the slab rises

- Filling and sealing the injection holes

However, a few of these steps will vary depending on the type of filler material used. For example, some filler materials need larger holes and have a longer curing time.

Although there are several options for filler material, the most common are polyurethane foam, such as we use here at Keystone Gun-Krete, and “slurry,” a mixture of water, soil, sand, and cement used in a process called “mudjacking.”

Let’s compare and contrast mudjacking with polyurethane foam injection.

Mudjacking

Mudjacking is a process in which technicians pump a mixture of water, soil, sand, and cement (called slurry) under the sunken concrete through drilled holes. The pressure lifts the slab to its original level.

Although mudjacking is cost-effective in the short term, since it’s usually a little cheaper than polyurethane foam injection, the result is not as durable. The heavy slurry further stresses the underlying soil, causing the slab to sink further over time.

At Keystone Gun-Krete, we want to offer the most cost-effective long-term solution. In the past, we’ve offered both mudjacking and polyurethane foam injection, and we’ve found that mudjacking didn’t hold up as well over time.

Polyurethane Foam Injection

Polyurethane foam is a durable and lightweight material that expands when injected under a concrete slab, filling voids and lifting the concrete.

Because it’s so lightweight, it doesn’t stress the soil like the heavy slurry used in mudjacking. This means the slab is less likely to continue sinking over time.

In addition, polyurethane foam has a quick curing time and is less invasive because it can be applied through small, penny-sized holes that are easier to patch compared to the larger holes required by mudjacking.

Although polyurethane foam often costs a little more upfront than mudjacking, it provides a more permanent solution at a competitive price.

Finding a Reputable Concrete-Lifting Contractor

Concrete lifting requires trained technicians and is not something you should attempt to DIY. If you live in Pennsylvania, Delaware, or Maryland, consider hiring Keystone Gun-Krete to expertly lift your concrete slab into place, ensuring it remains strong, stable, and beautiful for years.

We use state-of-the-art equipment and materials to ensure a durable and aesthetically pleasing repair. If you’re looking for quality workmanship and peace of mind knowing that the job will be done right the first time, we’d love to help!

Our rates vary depending on the size and scope of the job, but feel free to reach out to us for a free quote! We’ve been a trusted leader in concrete solutions for over 40 years, and we’re excited to work with you!